-

GRIP Type

SINCE 1986 Best Quality Price Satisfaction Timely Delivery YOUNGNAM METAL CO.. LTD.

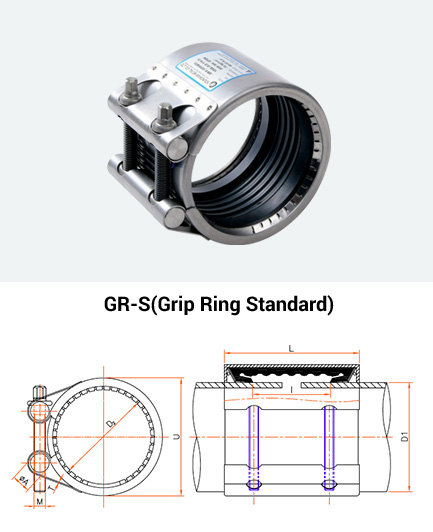

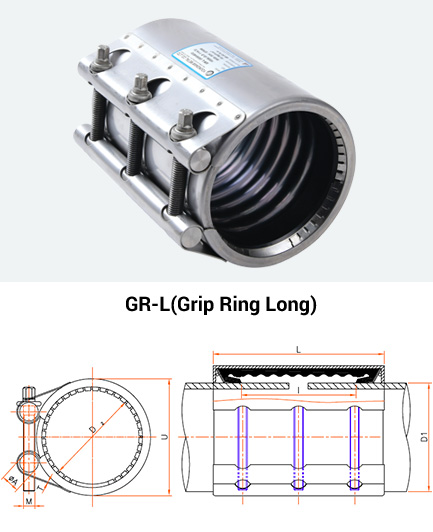

GRIP-RING PIPE COUPLING

(Grip Type)

GRIP RING- couplings join plain end pipes with axial restraint.

GR-coupling provide pull out resistance in excess of the couplings rated working pressure.

GR-coupling provide pull out resistance in excess of the couplings rated working pressure.

GR-S ※ PIPE O.D specifications are available in all sizes.

※ You can check by swiping the table left or right (swipe).

| SIZE | O/D (mm) | Range (mm) | M | L | ℓ | U | W.P | W.T | P (N·m (kgf·cm)) | |

|---|---|---|---|---|---|---|---|---|---|---|

| N.D (Inch) | D1 | D2 | Industrial | Ship | ||||||

| 15A (1/2″) | 21.3 21.7 22.0 | O/D±0.3 | M6 | 57 | 20 | 38 | 40 | 20 | 0.18 | 3~5 (30~50) |

| 20A (3/4″) | 26.9 26.7 27.2 | O/D ±0.5 | M6 | 57 | 20 | 47 | 40 | 20 | 0.21 | 4~6 (40~60) |

| 25A (1″) | 33.4 33.7 34.0 | O/D ±0.6 | M6 | 57 | 20 | 52 | 40 | 20 | 0.23 | 4~6 (40~60) |

| 32A (1-1/4″) | 40.9 42.2 42.4 42.7 | O/D ±0.6 | M8 | 57 | 20 | 64 | 40 | 20 | 0.34 | 10~12 (100~120) |

| 40A (1-1/2″) | 44.5 48.3 48.6 50.8 | O/D ±1.0 | M8 | 57 | 22 | 68 | 40 | 20 | 0.36 | 10~12 (100~120) |

| 50A (2″) | 54.0 57.0 60.3 60.5 | O/D ±1.0 | M10 | 80 | 30 | 84 | 36 | 18 | 0.80 | 15~18 (150~180) |

| 65A (2-1/2″) | 66.7 69.0 73.0 76.3 | O/D ±1.0 | M10 | 80 | 30 | 101 | 36 | 18 | 0.89 | 15~18 (150~180) |

| 80A (3″) | 79.8 84.0 88.9 89.1 | O/D ±1.5 | M12 | 108 | 50 | 117 | 32 | 16 | 1.56 | 40~50 (400~500) |

| 90A (3-1/2″) | 98.0 101.6 | O/D ±1.5 | M12 | 108 | 50 | 142 | 32 | 16 | 1.64 | 40~50 (400~500) |

| 100A (4″) | 104.8 106.3 108.0 114.3 | O/D ±1.5 | M12 | 108 | 50 | 142 | 32 | 16 | 1.77 | 40~50 (400~500) |

| 125A (5″) | 129.0 133.0 139.8 141.3 | O/D ±1.5 | M14 | 117 | 55 | 176 | 28 | 12 | 2.95 | 60~80 (600~800) |

| 150A (6″) | 154.0 159.0 165.2 168.3 | O/D ±1.5 | M14 | 117 | 55 | 201 | 28 | 12 | 3.15 | 60~80 (600~800) |

| 200A (8″) | 204.0 216.3 219.1 | O/D ±2.0 | M16 | 155 | 72 | 256 | 24 | 7 | 6.60 | 120~150 (1200~1500) |

| 250A (10″) | 254.0 267.4 273.1 | O/D ±2.0 | M16 | 155 | 65 | 300 | 20 | 7 | 7.55 | 120~150 (1200~1500) |

| 300A (12″) | 304.0 318.5 323.9 325.0 | O/D ±2.0 | M18 | 155 | 65 | 350 | 14 | 5 | 9.75 | 170~190 (1700~1900) |

| 350A (14″) | 355.6 | O/D ±2.0 | M18 | 155 | 65 | 400 | 14 | 5 | 10.58 | 170~190 (1700~1900) |

GR-L ※ PIPE O.D specifications are available in all sizes.

※ You can check by swiping the table left or right (swipe).

| SIZE | O/D (mm) | Range (mm) | M | L | ℓ | U | W.P | W.T | P (N·m (kgf·cm)) | |

|---|---|---|---|---|---|---|---|---|---|---|

| N.D (Inch) | D1 | D2 | Industrial | Ship | ||||||

| 15A (1.2″) | 20.0 21.3 21.7 22.0 | O/D±0.3 | M6 | 72 | 40 | 39 | 40 | 20 | 0.23 | 3~5 (30~50) |

| 20A (3/4″) | 25.0 26.9 26.7 27.2 | O/D ±0.5 | M6 | 72 | 40 | 47 | 40 | 20 | 0.26 | 4~6 (40~60) |

| 25A (1″) | 32.0 33.4 33.7 34.0 | O/D ±0.6 | M8 | 100 | 55 | 51 | 40 | 20 | 0.46 | 5~8 (50~80) |

| 32A (1-1/4″) | 40.9 42.2 42.4 42.7 | O/D ±0.6 | M8 | 100 | 55 | 62 | 40 | 20 | 0.53 | 10~12 (100~120) |

| 40A (1-1/2″) | 48.3 48.6 50.0 | O/D ±1.0 | M8 | 100 | 55 | 66 | 40 | 20 | 0.57 | 10~12 (100~120) |

| 50A (2″) | 60.3 60.5 . 63 | O/D ±1.0 | M10 | 139 | 84 | 81 | 36 | 18 | 1.29 | 15~18 (150~180) |

| 65A (2-1/2″) | 73.0 76.3 | O/D ±1.0 | M10 | 139 | 84 | 100 | 36 | 18 | 1.43 | 15~18 (150~180) |

| 80A (3″) | 88.9 89.1 | O/D ±1.5 | M12 | 203 | 122 | 115 | 32 | 16 | 2.83 | 40~50 (400~500) |

| 100A (4″) | 114.3 118.0 | O/D ±1.5 | M12 | 203 | 122 | 144 | 32 | 16 | 3.18 | 40~50 (400~500) |

| 125A (5″) | 139.8 141.3 | O/D ±1.5 | M14 | 204 | 128 | 175 | 28 | 12 | 4.80 | 60~80 (600~800) |

| 150A (6″) | 159.0 165.2 168.3 | O/D ±1.5 | M14 | 204 | 128 | 196 | 28 | 12 | 5.24 | 60~80 (600~800) |

| 200A (8″) | 216.3 219.1 | O/D ±2.0 | M16 | 255 | 157 | 260 | 24 | 7 | 10.74 | 120~150 (1200~1500) |

| 250A (10″) | 267.4 273.1 | O/D ±2.0 | M16 | 255 | 157 | 300 | 20 | 7 | 12.08 | 120~150 (1200~1500) |

| 300A (12″) | 318.5 323.9 325.0 | O/D ±2.0 | M18 | 255 | 157 | 350 | 14 | 5 | 15.60 | 170~190 (1700~1900) |

· N.D : Nominal Diameter (A)

· ℓ : Allowable Shrinkage/Expansion Clearance(m/m)

· D1 : Actual Outer Diameter of Pipe(m/m)

· T : Thickness of the coupling case(m/m)

· D2 : Min./Max. Allowable Limit for Pipe(m/m)

· U : Outer Diameter of Coupling(m/m)

· M : Fastener Bolt Size/Length(m/m)

· W.P : Working Pressure(㎏f·㎠)

· ØA : diameter of lock rod(m/m)

· W/T : Weight Per Unit(㎏)

· L : Coupling Width(m/m)

· W : Gap between pipes when installing

· P : Optimum Locking Torque Value Nm(㎏f·cm)

※ The specifications are subject to change for quality improvement.