-

Classification Test Rules

SINCE 1986 Best Quality Price Satisfaction Timely Delivery YOUNGNAM METAL CO.. LTD.

APPLICATION OF PIPE-COUPLING

Test Methods : IACS Req.2001 / Rev.3 2012

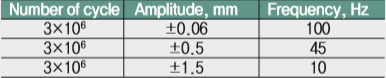

※ You can check by swiping the table left or right (swipe).

| Test Item | Socket Joint | Test Method | ||

|---|---|---|---|---|

| GR Type | MF Type | |||

| 1 | TIGHTNESS TEST | Applied | Applied | Connect a mechanical joint in the space between pipes,pressurize it with a pressure 1.5 times the design pressure and maintain it for 5 minutes. PASS if it is leak free. |

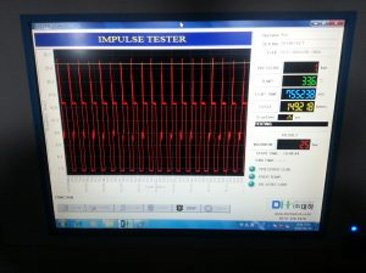

| 2 | VIBRATION TEST | Applied | ─ | Perform the three tests on the pipe connected to a mechanical joint by maintaining design pressure. PASS only if all three tests prove to be leak free. |

| 3 | PULSTATION TEST | Applied | ─ | A test to check whether an assembly with mechanical joints can withstand pressure pulsation. Increase the impact pressure to 1.5 times the design pressure from zero within a frequency range of 30~ 50 cycles per minute, with the number of cycles being over 500,000, and check for any leaks or signs of fault. PASS only if no faults are detected. |

| 4 | BURST PRESSURE TEST | Applied | Applied | A test intended to check whether an assembly that passed a watertight test can withstand a burst pressure four times the design pressure. PASS only if it is leak free even when the foregoing pressure is applied. |

| 5 | PULL-OUT TEST | Applied | ─ | When the load pressurized up to the design pressure and calculated by the following equation is applied to an assembly in the direction of axial load to verify that the assembly with a mechanical joint is not separated from the connected pipe under the axial load that can be generated while the assembly is in use. It must be leak free to be declared as PASS. |

| 6 | FIRE TEST | Applied | Applied | Expose an assembly with a mechanical joint to a flame at 800℃ for 30 minutes in a state where water is in circulation at over 80℃ under the design pressure of a joint. (Have the flame envelop the test material.) PASS only if there is no leak. |

| 7 | VACUUM TEST | Applied | Applied | Connect the assembly that has a mechanical joint to a vacuum pump to make the pressure 170hPa (absolute pressure). If the pressure is stabilized, separate the vacuum pump from the assembly with a mechanical joint being tested and keep it in this condition for 5 minutes. PASS only if no fault occurs in this state. |

| 8 | REPEATES ASSEMBLY TEST | Applied | ─ | Combine and separate the test material with a mechanical joint 10 times according to the manufacturer’s instructions and carry out the prescribed watertight test. PASS if there is no leak. |